Explore the biggest E-car charging station

in the world

Explore the biggest E-car charging station

in the world

Explore the biggest E-car charging station in the world

Explore the biggest E-car charging station in the world

Explore the biggest E-car charging station

in the world

For the first time the world renowned PALIS System is combined

with revolutionary E-charching technology,

the smartest parking app and international safety technology.

For the first time the world renowned PALIS System is combined

with revolutionary E-charching technology,

the smartest parking app and international safety technology.

For the first time the world renowned PALIS System is combined

with revolutionary E-charching technology,

the smartest parking app and international safety technology.

For the first time the world renowned PALIS System is combined

with revolutionary E-charching technology,

the smartest parking app and international safety technology.

For the first time the world renowned PALIS System is combined

with revolutionary E-charching technology, the smartest parking app and international safety technology.

Manufacturer elevator technology

Manufacturer elevator technology

Manufacturer elevator technology

Manufacturer elevator technology

PALIS®Automatic Parking GmbH & Co.KG

As a leading and experienced manufacturer of fully automated multi storey car parks, PALIS® offers longtime experience and a perfected product range. Sophisticated and functional systems are a fundamental requirement of PALIS®. At the beginning there was a fully functional prototype in a specially created facility. Only when the reliable function was ensured PALIS®; placed their system on the market. Since then, reliable and high quality parking systems have been built and put into operation time and again. The absolute flagship project are of course the car towers at VW in Wolfsburg.

PALIS®Automatic Parking GmbH & Co.KG

As a leading and experienced manufacturer of fully automated multi storey car parks, PALIS® offers longtime experience and a perfected product range. Sophisticated and functional systems are a fundamental requirement of PALIS®. At the beginning there was a fully functional prototype in a specially created facility. Only when the reliable function was ensured PALIS® placed their system on the market. Since then, reliable and high quality parking systems have been built and put into operation time and again. The absolute flagship project are of course the car towers at VW in Wolfsburg.

PALIS®Automatic Parking GmbH & Co.KG

As a leading and experienced manufacturer of fully automated multi storey car parks, PALIS® offers longtime experience and a perfected product range. Sophisticated and functional systems are a fundamental requirement of PALIS®. At the beginning there was a fully functional prototype in a specially created facility. Only when the reliable function was ensured PALIS® placed their system on the market. Since then, reliable and high quality parking systems have been built and put into operation time and again. The absolute flagship project are of course the car towers at VW in Wolfsburg.

PALIS®Automatic Parking GmbH & Co.KG

As a leading and experienced manufacturer of fully automated multi storey car parks, PALIS® offers longtime experience and a perfected product range. Sophisticated and functional systems are a fundamental requirement of PALIS®. At the beginning there was a fully functional prototype in a specially created facility. Only when the reliable function was ensured PALIS® placed their system on the market. Since then, reliable and high quality parking systems have been built and put into operation time and again. The absolute flagship project are of course the car towers at VW in Wolfsburg.

Parksystem Round PALIS

The automatic lift system "Round Palis" is based on a circular base area, which can be reduced to a quarter circle. The round base area allows for maximum space utilization and thus a massive construction volume savings.

Up to four high-speed lifts move independently on a centrally located lift column and transport the cars vertically into a multi-storey "parking rack". Using shuttle technology, the lift can pick up the cars and gently park them in the parking rack. The system is partially redundant and can compensate for the loss of an entry box with the aid of a shift platform. Between 50 and 500 cars find their place in the individual system, depending on the version. The entrance terminals are designed so that the user intuitively finds the right position, with the turning system fine-tuning and turning the car 180 degrees to the lift. When the car is parked, the car is handed over to the user in the exit direction.

The system was developed and patented by the company Palis from Germany, but until now only used in aboveground parking garages. The most well-known example are the park towers of the VW Autostadt in Wolfsburg. The two towers are even listed under the title "fastest automatic parking system in the world" in the Guinness Book of Records.

Description:

- high-speed automated parking system

- round shape / segments of a circle

- for 50 to 500 parking spaces per system

- simultaneous vertical and horizontal movement

- architecturally remarkable

- small footprint

- location underground and above ground

- space saving of upto 50%

Components of a Round PALIS Automatic Car Park:

Upto 4 high-speed lifts are moving independently on a centered lift column. With the ability to rotate upto 180° they are serving the parking spaces.

Parksystem Round PALIS

The automatic lift system "RoundPalis" is based on a circular base area, which can be reduced to a quarter circle. The round base area allows for maximum space utilization and thus a massive construction volume savings.

Up to four high-speed lifts move independently on a centrally located lift column and transport the cars vertically into a multi-storey "parking rack". Using shuttle technology, the lift can pick up the cars and gently park them in the parking rack. The system is partially redundant and can compensate for the loss of an entry box with the aid of a shift platform. Between 50 and 500 cars find their place in the individual system, depending on the version. The entrance terminals are designed so that the user intuitively finds the right position, with the turning system fine-tuning and turning the car 180 degrees to the lift. When the car is parked, the car is handed over to the user in the exit direction.

The system was developed and patented by the company Palis from Germany, but until now only used in aboveground parking garages. The most well-known example are the park towers of the VW Autostadt in Wolfsburg. The two towers are even listed under the title "fastest automatic parking system in the world" in the Guinness Book of Records.

Description:

- high-speed automated parking system

- round shape / segments of a circle

- for 50 to 500 parking spaces per system

- simultaneous vertical and horizontal movement

- architecturally remarkable

- small footprint

- location underground and above ground

- space saving of upto 50%

Components of a Round PALIS Automatic Car Park:

Upto 4 high-speed lifts are moving independently on a centered lift column. With the ability to rotate upto 180° they are serving the parking spaces.

Parksystem Round PALIS

The automatic lift system "RoundPalis" is based on a circular base area, which can be reduced to a quarter circle. The round base area allows for maximum space utilization and thus a massive construction volume savings.

Up to four high-speed lifts move independently on a centrally located lift column and transport the cars vertically into a multi-storey "parking rack". Using shuttle technology, the lift can pick up the cars and gently park them in the parking rack. The system is partially redundant and can compensate for the loss of an entry box with the aid of a shift platform. Between 50 and 500 cars find their place in the individual system, depending on the version. The entrance terminals are designed so that the user intuitively finds the right position, with the turning system fine-tuning and turning the car 180 degrees to the lift. When the car is parked, the car is handed over to the user in the exit direction.

The system was developed and patented by the company Palis from Germany, but until now only used in aboveground parking garages. The most well-known example are the park towers of the VW Autostadt in Wolfsburg. The two towers are even listed under the title "fastest automatic parking system in the world" in the Guinness Book of Records.

Description:

- high-speed automated parking system

- round shape / segments of a circle

- for 50 to 500 parking spaces per system

- simultaneous vertical and horizontal movement

- architecturally remarkable

- small footprint

- location underground and above ground

- space saving of upto 50%

Components of a Round PALIS Automatic Car Park:

Upto 4 high-speed lifts are moving independently on a centered lift column. With the ability to rotate upto 180° they are serving the parking spaces.

Parksystem Round PALIS

The automatic lift system "RoundPalis" is based on a circular base area, which can be reduced to a quarter circle. The round base area allows for maximum space utilization and thus a massive construction volume savings.

Up to four high-speed lifts move independently on a centrally located lift column and transport the cars vertically into a multi-storey "parking rack". Using shuttle technology, the lift can pick up the cars and gently park them in the parking rack. The system is partially redundant and can compensate for the loss of an entry box with the aid of a shift platform. Between 50 and 500 cars find their place in the individual system, depending on the version. The entrance terminals are designed so that the user intuitively finds the right position, with the turning system fine-tuning and turning the car 180 degrees to the lift. When the car is parked, the car is handed over to the user in the exit direction.

The system was developed and patented by the company Palis from Germany, but until now only used in aboveground parking garages. The most well-known example are the park towers of the VW Autostadt in Wolfsburg. The two towers are even listed under the title "fastest automatic parking system in the world" in the Guinness Book of Records.

Description:

- high-speed automated parking system

- round shape / segments of a circle

- for 50 to 500 parking spaces per system

- simultaneous vertical and horizontal movement

- architecturally remarkable

- small footprint

- location underground and above ground

- space saving of upto 50%

Components of a Round PALIS Automatic Car Park:

Upto 4 high-speed lifts are moving independently on a centered lift column. With the ability to rotate upto 180° they are serving the parking spaces.

E-Mobility

E-Mobility

E-Mobility

E-Mobility

Driveway controls

After parking the vehicle in the entry box, the vehicle is measured in terms of size and weight. If the car is too big or too heavy for the parking system, the process is stopped immediately and the driver is asked to leave the parking box.

If both the size and the weight (3 tones at a time) are within the permissible values, parking can be continued.

Driveway controls

After parking the vehicle in the entry box, the vehicle is measured in terms of size and weight. If the car is too big or too heavy for the parking system, the process is stopped immediately and the driver is asked to leave the parking box. If both the size and the weight (3 tones at a time) are within the permissible values, parking can be continued.

Driveway controls

After parking the vehicle in the entry box, the vehicle is measured in terms of size and weight. If the car is too big or too heavy for the parking system, the process is stopped immediately and the driver is asked to leave the parking box. If both the size and the weight (3 tones at a time) are within the permissible values, parking can be continued.

Driveway controls

After parking the vehicle in the entry box, the vehicle is measured in terms of size and weight. If the car is too big or too heavy for the parking system, the process is stopped immediately and the driver is asked to leave the parking box.

If both the size and the weight (3 tones at a time) are within the permissible values, parking can be continued.

Passenger control

After leaving and unloading the car, the driver has to confirm at the push of a button that there is no living being left in the car.

With the help of state-of-the-art sensors, it is checked whether this input is correct. Only then the car is pulled into the garage.

Passenger control

After leaving and unloading the car, the driver has to confirm at the push of a button that there is no living being left in the car. With the help of state-of-the-art sensors, it is checked whether this input is correct. Only then the car is pulled into the garage.

Passenger control

After leaving and unloading the car, the driver has to confirm at the push of a button that there is no living being left in the car.

With the help of state-of-the-art sensors, it is checked whether this input is correct. Only then the car is pulled into the garage.

Passenger control

After leaving and unloading the car, the driver has to confirm at the push of a button that there is no living being left in the car.

With the help of state-of-the-art sensors, it is checked whether this input is correct. Only then the car is pulled into the garage.

App technology

App technology

App technology

App technology

Park-App by Accessio

The Graz start-up company Accessio convinces in the field of "Smart Parking" with its park app "ARIVO", which is already used in numerous companies (eg Steiermärkische Sparkasse Graz, SFG Impulse Center, GWS). Through this concept, there is a change in the area of parking: away from the barrier systems with ticket billing to app-controlled access controls and digital billing. Charged with additional features, the app is ideal for use in the SUP system.

Park- App by Accessio

The Graz start-up company Accessio convinces in the field of "Smart Parking" with its park app "ARIVO", which is already used in numerous companies (eg Steiermärkische Sparkasse Graz, SFG Impulse Center, GWS). Through this concept, there is a change in the area of parking: away from the barrier systems with ticket billing to app-controlled access controls and digital billing. Charged with additional features, the app is ideal for use in the SUP system.

Park- App by Accessio

The Graz start-up company Accessio convinces in the field of "Smart Parking" with its park app "ARIVO", which is already used in numerous companies (eg Steiermärkische Sparkasse Graz, SFG Impulse Center, GWS). Through this concept, there is a change in the area of parking: away from the barrier systems with ticket billing to app-controlled access controls and digital billing. Charged with additional features, the app is ideal for use in the SUP system.

Park- App by Accessio

The Graz start-up company Accessio convinces in the field of "Smart Parking" with its park app "ARIVO", which is already used in numerous companies (eg Steiermärkische Sparkasse Graz, SFG Impulse Center, GWS). Through this concept, there is a change in the area of parking: away from the barrier systems with ticket billing to app-controlled access controls and digital billing. Charged with additional features, the app is ideal for use in the SUP system.

Advantages:

- Time control (how long do I have to wait?

- Digital billing

- Safety system with license plate recognition

- Utilization control for operator car sharing management

- Fast handling

Smart Parking

A smartphone or smartwatch app supports the parking system. It allows the call of the parked car and indicates the remaining time until pickup. The billing is done digitally.

Advantages:

- Time control (how long do I have to wait?

- Digital billing

- Safety system with license plate recognition

- Utilization control for operator car sharing management

- Fast handling

Smart Parking

A smartphone or smartwatch app supports the parking system. It allows the call of the parked car and indicates the remaining time until pickup. The billing is done digitally.

Advantages:

- Time control (how long do I have to wait?

- Digital billing

- Safety system with license plate recognition

- Utilization control for operator car sharing management

- Fast handling

Smart Parking

A smartphone or smartwatch app supports the parking system. It allows the call of the parked car and indicates the remaining time until pickup. The billing is done digitally.

Advantages:

- Time control (how long do I have to wait?

- Digital billing

- Safety system with license plate recognition

- Utilization control for operator car sharing management

- Fast handling

Smart Parking

A smartphone or smartwatch app supports the parking system. It allows the call of the parked car and indicates the remaining time until pickup. The billing is done digitally.

Advantages:

- Time control (how long do I have to wait?

- Digital billing

- Safety system with license plate recognition

- Utilization control for operator car sharing management

- Fast handling

Smart Parking

A smartphone or smartwatch app supports the parking system. It allows the call of the parked car and indicates the remaining time until pickup. The billing is done digitally.

Manufacturer control technology

E-Mobility

Manufacturer control technology

E-Mobility

Manufacturer control technology E-Mobility

Manufacturer control technology

E-Mobility

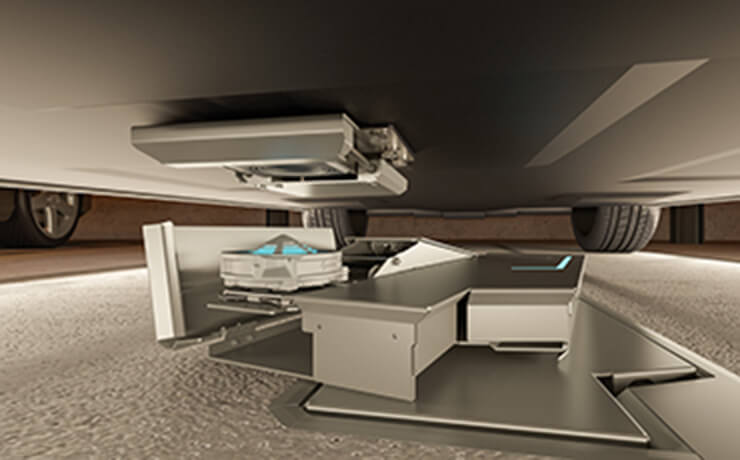

Revolutionary charging experience

When an electric vehicle with the VOLTERIO charging system approaches to a respective parking lot, the VOLTERIO base unit automatically starts to communicate with the vehicle unit via an encrypted wireless connection. The electric vehicle only needs to be parked roughly over the base unit. Guided by an ultrasound based micro-navigation system the base unit automatically connects after ensuring the correct vehicle position. After checking authorization, the charging process starts automatically or can be scheduled by an intelligent charging management. Recharging will be something you don’t have to care about - everything happens automatically.

Revolutionary charging experience

When an electric vehicle with the VOLTERIO charging system approaches to a respective parking lot, the VOLTERIO base unit automatically starts to communicate with the vehicle unit via an encrypted wireless connection. The electric vehicle only needs to be parked roughly over the base unit. Guided by an ultrasound based micro-navigation system the base unit automatically connects after ensuring the correct vehicle position. After checking authorization, the charging process starts automatically or can be scheduled by an intelligent charging management. Recharging will be something you don’t have to care about - everything happens automatically.

Revolutionary charging experience

When an electric vehicle with the VOLTERIO charging system approaches to a respective parking lot, the VOLTERIO base unit automatically starts to communicate with the vehicle unit via an encrypted wireless connection. The electric vehicle only needs to be parked roughly over the base unit. Guided by an ultrasound based micro-navigation system the base unit automatically connects after ensuring the correct vehicle position. After checking authorization, the charging process starts automatically or can be scheduled by an intelligent charging management. Recharging will be something you don’t have to care about - everything happens automatically.

Revolutionary charging experience

When an electric vehicle with the VOLTERIO charging system approaches to a respective parking lot, the VOLTERIO base unit automatically starts to communicate with the vehicle unit via an encrypted wireless connection. The electric vehicle only needs to be parked roughly over the base unit. Guided by an ultrasound based micro-navigation system the base unit automatically connects after ensuring the correct vehicle position. After checking authorization, the charging process starts automatically or can be scheduled by an intelligent charging management. Recharging will be something you don’t have to care about - everything happens automatically.

Fully automatic charging

VOLTERIO (former known as NRG-X) represents and industrializes a ground-breaking approach that is redefining charging of electric vehicles. It is truly the smartest, fully automatic, efficient, affordable and high power charging solution. VOLTERIO does not require precise parking and can be easily integrated/retrofitted to almost every electric vehicle. Therefore, it is the ideal solution for convenient every day charging primarily at home. The system comprises two basic components:

Vehicle unit - Retrofitted/integrated in the car’s underbody

Base unit - The charging robot on the parking space

Fully automatic charging

VOLTERIO (former known as NRG-X) represents and industrializes a ground-breaking approach that is redefining charging of electric vehicles. It is truly the smartest, fully automatic, efficient, affordable and high power charging solution. VOLTERIO does not require precise parking and can be easily integrated/retrofitted to almost every electric vehicle. Therefore, it is the ideal solution for convenient every day charging primarily at home. The system comprises two basic components:

Vehicle unit - Retrofitted/integrated in the car’s underbody

Base unit - The charging robot on the parking space

Fully automatic charging

VOLTERIO (former known as NRG-X) represents and industrializes a ground-breaking approach that is redefining charging of electric vehicles. It is truly the smartest, fully automatic, efficient, affordable and high power charging solution. VOLTERIO does not require precise parking and can be easily integrated/retrofitted to almost every electric vehicle. Therefore, it is the ideal solution for convenient every day charging primarily at home. The system comprises two basic components:

Vehicle unit - Retrofitted/integrated in the car’s underbody

Base unit - The charging robot on the parking space

Fully automatic charging

VOLTERIO (former known as NRG-X) represents and industrializes a ground-breaking approach that is redefining charging of electric vehicles. It is truly the smartest, fully automatic, efficient, affordable and high power charging solution. VOLTERIO does not require precise parking and can be easily integrated/retrofitted to almost every electric vehicle. Therefore, it is the ideal solution for convenient every day charging primarily at home. The system comprises two basic components:

Vehicle unit - Retrofitted/integrated in the car’s underbody

Base unit - The charging robot on the parking space

Smartest way to connect

Charging via a physical connection to the vehicle’s underbody is not only the most logical approach, but also enables the simplest possible robotic for an automatic connection. Thanks to the revolutionary self-centering, twist-independent, high power connector design, even the angular orientation of the parking vehicle does not matter. Unlike inductive charging, whereas the vehicle must be positioned very precisely, the base unit can compensate for large parking misalignments of even 0,5 x 0,5 m. Charging was never that simple - park and go away.

Smartest way to connect

Charging via a physical connection to the vehicle’s underbody is not only the most logical approach, but also enables the simplest possible robotic for an automatic connection. Thanks to the revolutionary self-centering, twist-independent, high power connector design, even the angular orientation of the parking vehicle does not matter. Unlike inductive charging, whereas the vehicle must be positioned very precisely, the base unit can compensate for large parking misalignments of even 0,5 x 0,5 m. Charging was never that simple - park and go away.

Smartest way to connect

Charging via a physical connection to the vehicle’s underbody is not only the most logical approach, but also enables the simplest possible robotic for an automatic connection. Thanks to the revolutionary self-centering, twist-independent, high power connector design, even the angular orientation of the parking vehicle does not matter. Unlike inductive charging, whereas the vehicle must be positioned very precisely, the base unit can compensate for large parking misalignments of even 0,5 x 0,5 m. Charging was never that simple - park and go away.

Smartest way to connect

Charging via a physical connection to the vehicle’s underbody is not only the most logical approach, but also enables the simplest possible robotic for an automatic connection. Thanks to the revolutionary self-centering, twist-independent, high power connector design, even the angular orientation of the parking vehicle does not matter. Unlike inductive charging, whereas the vehicle must be positioned very precisely, the base unit can compensate for large parking misalignments of even 0,5 x 0,5 m. Charging was never that simple - park and go away.

Statics and Realisation

Statics and Realisation

Statics and Realisation

Statics and Realisation

Static principle

In the first consideration, an overlapping bored pile wall is considered as a static principle. In this technique, holes in the diameter of the pile are sunk. Then the reinforcement cage is lifted and the borehole filled with concrete. Only then does the excavation of the inner area begin.

The advantage here is in the time and cost savings, as a conventional mine protection and formwork would be very expensive to produce. The sealing is done with the system brown tub.

Static principle

In the first consideration, an overlapping bored pile wall is considered as a static principle. In this technique, holes in the diameter of the pile are sunk. Then the reinforcement cage is lifted and the borehole filled with concrete. Only then does the excavation of the inner area begin. The advantage here is in the time and cost savings, as a conventional mine protection and formwork would be very expensive to produce. The sealing is done with the system brown tub.

Static principle

In the first consideration, an overlapping bored pile wall is considered as a static principle. In this technique, holes in the diameter of the pile are sunk. Then the reinforcement cage is lifted and the borehole filled with concrete. Only then does the excavation of the inner area begin.

The advantage here is in the time and cost savings, as a conventional mine protection and formwork would be very expensive to produce. The sealing is done with the system brown tub.

Static principle

In the first consideration, an overlapping bored pile wall is considered as a static principle. In this technique, holes in the diameter of the pile are sunk. Then the reinforcement cage is lifted and the borehole filled with concrete. Only then does the excavation of the inner area begin.

The advantage here is in the time and cost savings, as a conventional mine protection and formwork would be very expensive to produce. The sealing is done with the system brown tub.

Static principle

In the first consideration, an overlapping bored pile wall is considered as a static principle. In this technique, holes in the diameter of the pile are sunk. Then the reinforcement cage is lifted and the borehole filled with concrete. Only then does the excavation of the inner area begin.

The advantage here is in the time and cost savings, as a conventional mine protection and formwork would be very expensive to produce. The sealing is done with the system brown tub.

Large bored piles By the system "rotary drilling Kelly", which offers the company Keller Grundbau GMBH, a pile boring in a depth of up to 40m can be made, with diameters of 620mm, 880mm, 1180mm and 1500mm are selectable.

The approximately 120-tonne drill rig was selected on the premise that even limited-space urban projects could easily be carried out. * Another major benefit of the system is the elimination of a conventional excavation backup, which would require additional space around the pit. Due to the anticipated formation of the supporting ring before excavation this is not necessary.

Source: http://www.kellergrundbau.at/

Large bored piles By the system "rotary drilling Kelly", which offers the company Keller Grundbau GMBH, a pile boring in a depth of up to 40m can be made, with diameters of 620mm, 880mm, 1180mm and 1500mm are selectable.

The approximately 120-tonne drill rig was selected on the premise that even limited-space urban projects could easily be carried out. * Another major benefit of the system is the elimination of a conventional excavation backup, which would require additional space around the pit. Due to the anticipated formation of the supporting ring before excavation this is not necessary.

Source: http://www.kellergrundbau.at/

Large bored piles By the system "rotary drilling Kelly", which offers the company Keller Grundbau GMBH, a pile boring in a depth of up to 40m can be made, with diameters of 620mm, 880mm, 1180mm and 1500mm are selectable.

The approximately 120-tonne drill rig was selected on the premise that even limited-space urban projects could easily be carried out. * Another major benefit of the system is the elimination of a conventional excavation backup, which would require additional space around the pit. Due to the anticipated formation of the supporting ring before excavation this is not necessary.

Source: http://www.kellergrundbau.at/

Large bored piles By the system "rotary drilling Kelly", which offers the company Keller Grundbau GMBH, a pile boring in a depth of up to 40m can be made, with diameters of 620mm, 880mm, 1180mm and 1500mm are selectable.

The approximately 120-tonne drill rig was selected on the premise that even limited-space urban projects could easily be carried out. * Another major benefit of the system is the elimination of a conventional excavation backup, which would require additional space around the pit. Due to the anticipated formation of the supporting ring before excavation this is not necessary.

Source: http://www.kellergrundbau.at/

SUP SYSTEM HOLDING

Jakominiplatz 1

8010 Graz/Austria

info@sup-system.com

SUP SYSTEM HOLDING

Kaiserfeldgasse 1

8010 Graz/Austria

info@sup-system.com

SUP SYSTEM HOLDING

Kaiserfeldgasse 1

8010 Graz/Austria

info@sup-system.com

SUP SYSTEM HOLDING

Kaiserfeldgasse 1

8010 Graz/Austria

info@sup-system.com

SUP SYSTEM HOLDING

Kaiserfeldgasse 1

8010 Graz/Austria

info@sup-system.com

LEGAL INFORMATIONS

LEGAL INFORMATIONS

LEGAL INFORMATIONS

LEGAL INFORMATIONS

LEGAL INFORMATIONS